High and Low Viscosity Liquids

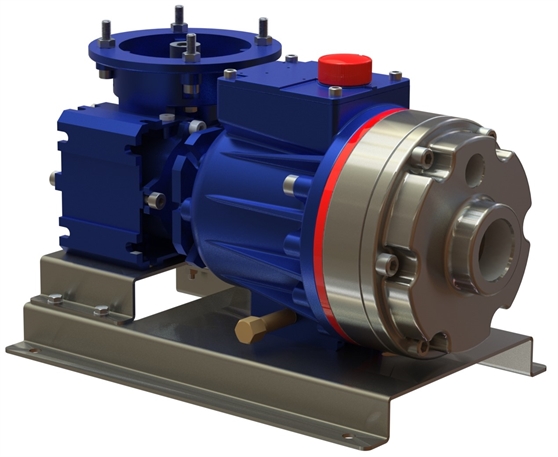

With the correct pump selection and system design, the Hydra-Cell® seal-less pump has the capability to pump viscous liquids (i.e., solvents, hot water, turpentine, glues, resins, and thick slurries) up to 20,000 cP.

The pumping action of the Hydra-Cell makes it a true positive displacement diaphragm pump at both high and low viscosities, and the flow rate is independent of discharge pressure, ensuring delivery of a predictable flow rate for a consistent process.

Pumps with dynamic seals can ‘leak’ low viscosity liquids past a contact area of rotating surface and static casing, resulting in a loss of flow. Flow rate loss increases as pressure rises and, through time with increasing wear at the rotating contact surface. At high pressure or high liquid temperature, risks increase sharply. Heating a liquid will typically reduce its viscosity, and as it thins it becomes more likely to leak past a seal or contact area.

Working at high pressure also exposes the pump to increased wear. In the Hydra-Cell seal-less diaphragm pump, this declining performance cycle associated with low viscosity liquids does not occur because there are no dynamic seals in the design. Unlike many competing technologies, the Hydra-Cell pump does not require lubricating process fluids to prevent internal component wear and is capable of running dry indefinitely, without damage.

When pumping high viscosity liquids, the spring-loaded disk design of the Hydra-Cell check valves overcomes the “floating” issues associated with vertical ball-and-seat valves. Many high viscosity materials are shear sensitive. Hydra-Cell's horizontal check valves have proven to have a low shear pumping action to preserve the structure of shear sensitive high viscosity liquids.

With no dynamic seals in its design, Hydra-Cell pumps have successfully replaced other pump technologies with dynamic seals, resulting in energy savings, lower maintenance and repair costs and sustaining system performance due to less down time.

Do you need help to reliably handle your process liquid?

Low NPSH due to High vapour pressure?

Need assistance or support with NPSH in terms of system design?

Are you replacing other pump technologies for abrasive/slurry duty application?

Our technical engineers can assist with selecting a Hydra-Cell seal-less pump to reliably handle your process liquid.

Hydra-Cell® Seal-less Pumps Reliably Handle High and Low Viscosity Liquids

- Acid Solution

- Adhesive

- Algae Solution

- Alkane

- Alumina Slurry

- Amine

- Ammonia

- Animal Fats

- Aqueous Emulsion

- Beer

- Benzine Waste

- Benzol

- Bio Oil

- Blended Diesel

- Blowing Agent

- Brackish Water

- Brine Solution

- Butane

- Butylacetate

- Calcium Carbonate

- Calcium Chloride

- Calcium Peroxide

- Carbon Hydrogen Concentrate

- Ceramic Slurry

- Chalk

- Chlorine Biocide

- Cleaning Solution

- Colour Dye

- Condensed Milk

- Corrosion Inhibitor

- Decoking Mix

- Deferoxamine

- De-Ionised Water

- Detergent

- Diesel

- Dye

- Ethyl Acetate

- Ethyl Lactate

- Ethylene Glycol

- Flotation Reagent

- Formation Water

- Freon

- Furnace Oil

- Gas Condensate

- Gasoline

- Heptane

- Hexane

- Hot Water

- Hydrocarbons

- Hydrochloric Acid

- Hydrogen Peroxide

- Hygienic Liquids

- Ink

- Isobutane

- Kerosene Jet A1

- Latex

- Leachate

- Lecithin

- Lime Slurry

- Liquid Petroleum Gas (LPG)

- Machine Tool Coolant

- Mercaptan

- Methane

- Methanol

- Methanol and Glycol (MEG)

- Methyl Formate

- Methylaniline

- Methylene Diphenyl Diisocyanate (MDI)

- Milk

- Monoethanolamine

- Mono-Ethylene Glycol

- Monomers

- Motor Spirit Fuels

- Mud Slurry

- Naphtha

- Natural Gas Liquids

- Nitric Acid (HNO3)

- Oil

- Organic Solvents

- Paint

- Pentane

- Perfume

- pH Stabiliser

- Phosphate

- Phosphoric Acid

- Polyester Resin

- Polyisocyanurate

- Polymer

- Polyol

- Printing Ink

- Produced Water

- Propane

- Proprietary Liquids

- Propylene

- Rape Seed Oil

- Raw Alcohol

- Recycled Water

- Refrigerants

- Resin

- Salt Water

- Seawater

- Sodium Hydroxide

- Sodium Hypochlorite

- Sodium Tripolyphosphate

- Solvent

- Soured Water

- Starch Glue

- Steam Condensate

- Sulphuric Acid

- Sweet Diesel

- Synthetic Emulsion

- Tetramethyl

- Titanium Dioxide

- Titanium Oxide

- Tri-Ethylene Glycol (TEG)

- Turpentine

- Urea

- Vinyl Acetate

- Viscous Resins

- Waste Oil

- Water

- Water Based Paint

- Water with Cleaning Agents

Request a technical support meeting online

CALL +44 (0) 1252 816847