MACHINE TOOL HIGH-PRESSURE COOLANT PUMPS

Visit our new Machine Tool website >>

For over 40 years, Wanner has experience in design, manufacturing and supplying Hydra-Cell high pressure coolant pumps into the metal cutting industry; supporting customers globally.

Hydra-Cell high-pressure coolant pumps are used by many machine tool manufacturers as well as stand alone high pressure coolant system producers. Fully integrated in CNC turning machines and grinders, Hydra-Cell high pressure coolant pumps offer energy savings of up to 20% when compared with other pump technologies used. Hydra-Cell high pressure coolant pumps are not damaged by fines that may inadvertently bypass filtration systems and can run dry indefinitely.

True positive displacement pumps, the flow rate of Hydra-Cell machine tool coolant pumps is directly proportional to the motor speed and is virtually unaffected by system pressure, making them highly controllable and easy to integrate in machine tool systems. As there are no dynamic seals to wear, this performance is consistent through the life of the pump.

Seal-less design means that fine filtration is not required to protect the Hydra-Cell pump. Particles as large as 500 microns in diameter can be tolerated. Filtration levels can be matched to the work piece or tooling, saving costs on ancillary equipment. Its ability to handle particles also makes it ideal for grinding wheel cleaning and for deep hole drilling.

Hydra-Cell pumps can handle any type of coolant - solvent-based, water-based mineral or synthetic oil emulsions, or neat oil - as well as the dielectric fluids and DI water used in EDM drilling and the abrasive slurries in ECM drilling operations. The pumps can run dry without damage.

Today's high pressure coolant systems can be subject to foaming problems. Foaming coolant entering any pumps can cause areas of localised dry running. This will cause immediate damage to pumps with dynamic seals. Although not ideal conditions for any pump, the Hydra-Cell seal-less design means that it does not suffer this immediate damage.

Model options allow pumping at pressures up to 170 bar (2500 psi). Maintenance requirements are minimal. High pumping efficiency reduces motor size and energy consumption.

All the above features mean that the Hydra-Cell pumps used in high pressure coolant delivery offer the user the widest operating window and make it the best technology for tolerating operator error.

See below for application examples from information supplied by customers

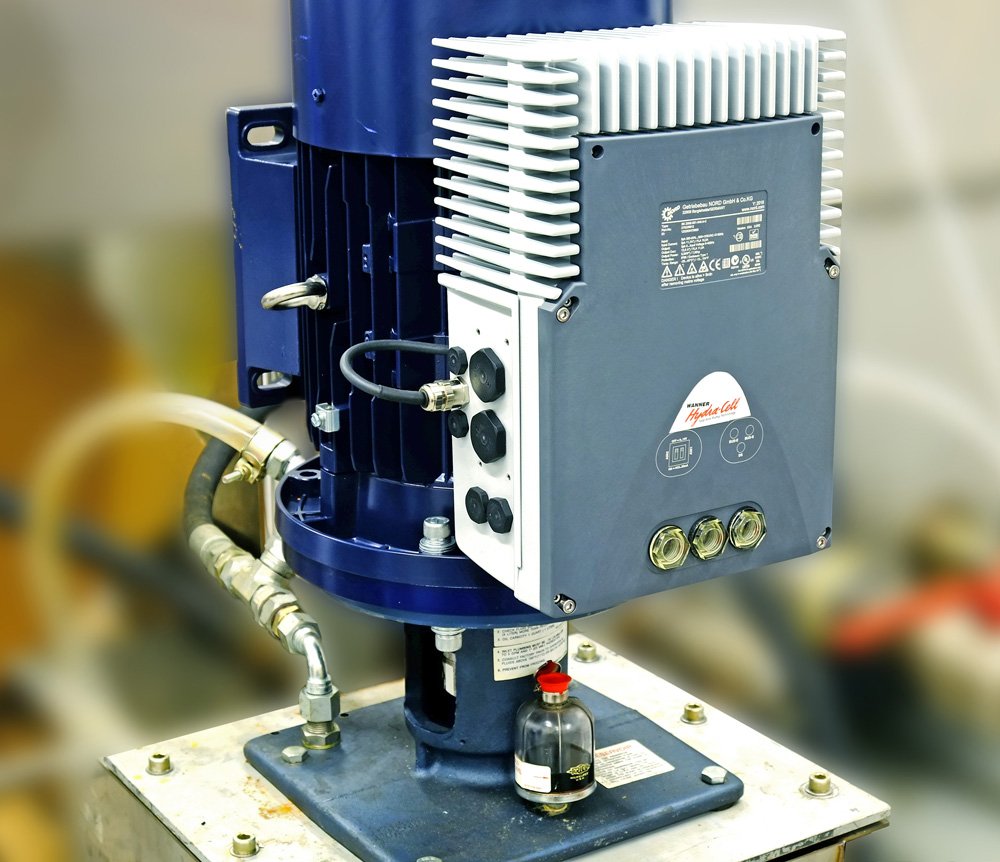

Hydra-Cell® seal-less, high-pressure coolant pumps with intelligent pump control (patent pending)

Maximise productivity with Hydra-Cell seal-less design - the most energy-efficient, high pressure coolant pump for your machine tool processes, whether you are an end user, CNC machine builder, high pressure coolant or filtration manufacturer. Visit our new Machine Tool website >>

The most energy-efficient, high-pressure coolant pump with ultimate controllability and lowest cost of ownership.

Careers

Request a technical support meeting online

CALL +44 (0) 1252 816847