Hydra-Cell® Pumps in Downstream Applications - BTX Aromatic Processing Pumps

Keep your processes producing for a more sustainable future - safely, reliably and efficiently with lower energy usage, 100% leak-free, reduced maintenance for a lower total cost of ownership.

"Pulse-Free" Processing of Benzene, Toluene and Xylene

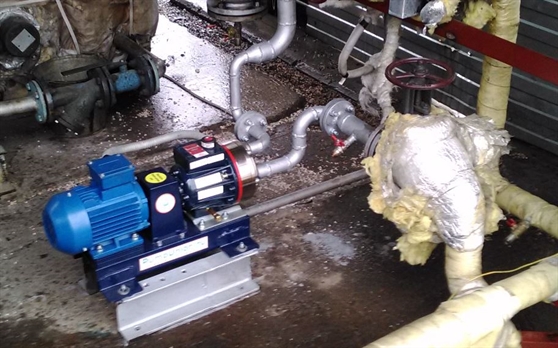

An oil refinery in the Kemerovo region of Russia with a forecast capacity of 6 million tons per year,is pivotal in the development of fuel and energy in Western Siberia. They needed a pump to feed BTX (Butane, Toluene, Xylene) into a catalytic converter. It was critical for the flow to be pulse-free as pulses can damage the catalytic cells.

The solution was found with a Hydra-Cell® pump.

Process Challenges

- Pumping non lubricating aggressive solvents - keeping them 100% contained

- Pulse-free flow to protect the catalytic cells

Hydra-Cell® Pump Advantages

No Seals. No Packing.

- Pumped liquid 100% contained - zero leakage

- Non lubricating low viscosity liquids pumped - safely & reliably

Multiple Diaphragms in a Single Pump Head

- Smooth discharge flow rate

- Elimination of pulsation dampeners - cost and maintenance saving

- Elimination of excessive vibration and pipe strain