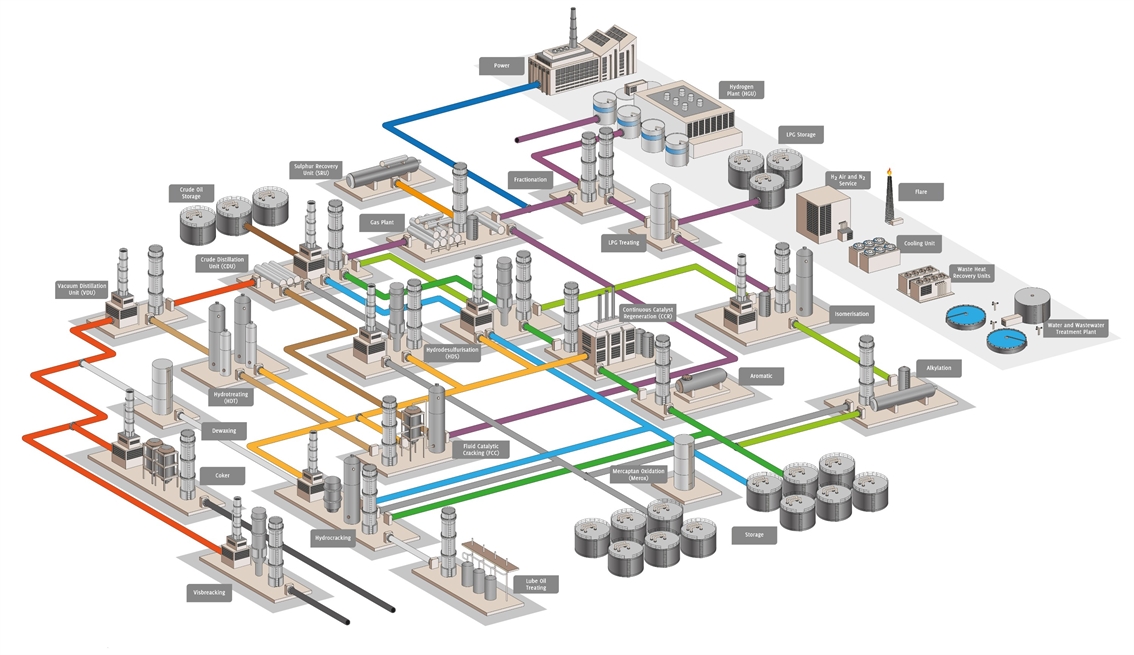

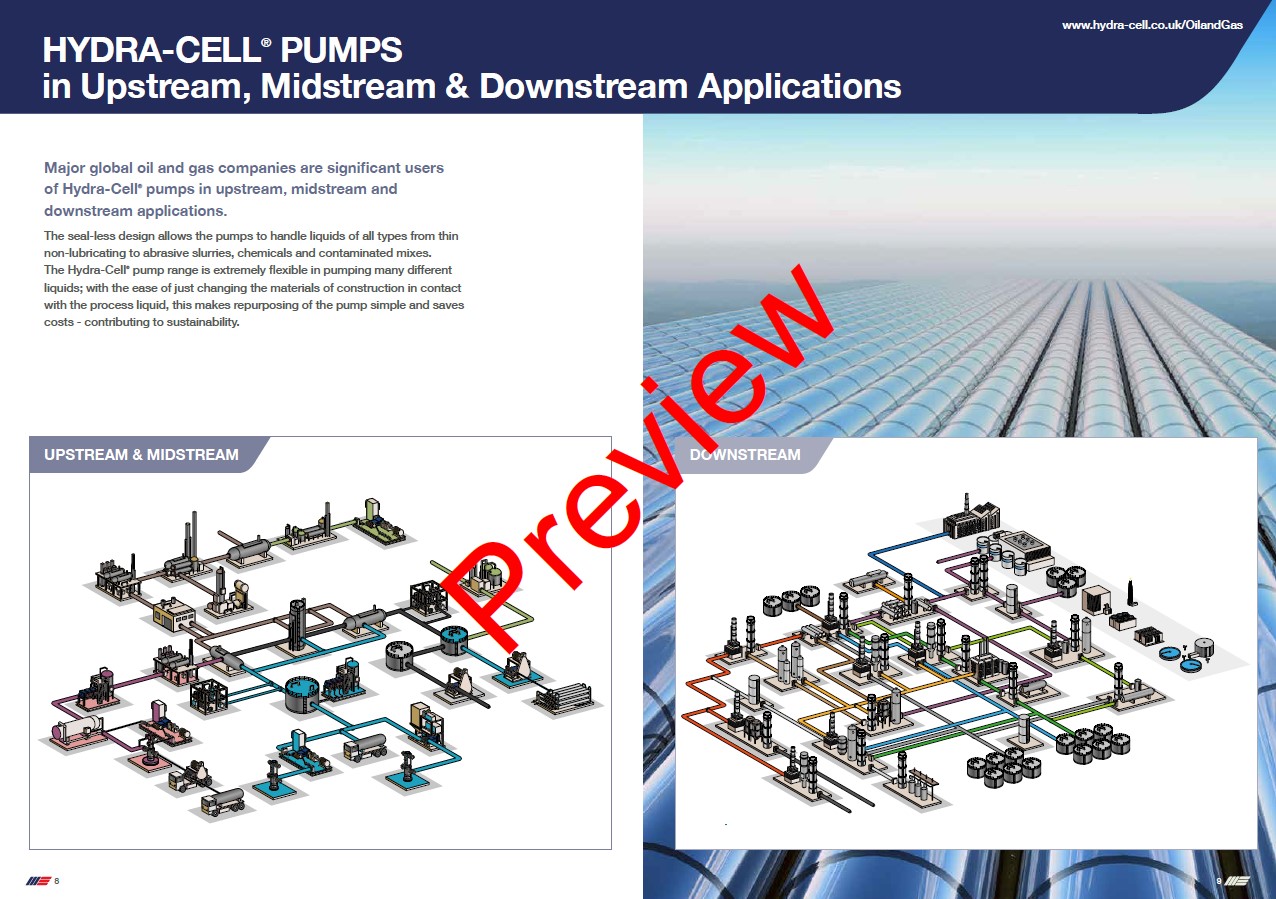

Hydra-Cell® Pumps in Downstream Applications

Keep your processes producing for a more sustainable future - safely, reliably and efficiently for a lower total cost of ownership.

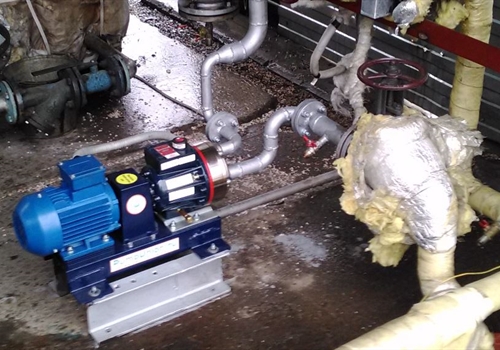

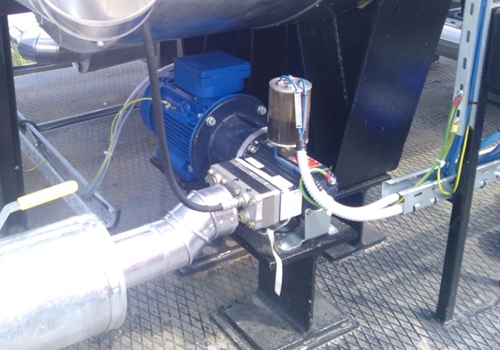

Protecting operators and the environment - 100% leak-free

No ground contamination, no spillage of hazardous chemistry when injecting hot Monoethanolamine, Benzene, Toluene and Xylene; keeping Naphtha and Methanol 100% and safely contained with zero emissions.

Hydra-Cell®’s range of EX-certified pumps are independantly certified by third party approval bodies to offer complete peace of mind for ATEX/hazardous areas.

Reduced maintenance costs - eliminate seal and packing maintenance

High reliability and smooth dosing of slurries; reliably handling liquids with particles such as sand and transferring mixtures of hydrocarbons and recycled oil and flammable solvent waste products.

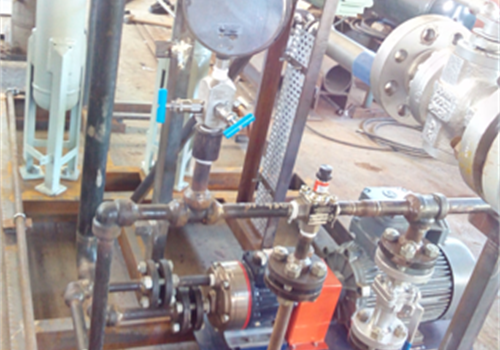

Reduced energy consumption

Hydra-Cell® API674 & API675 pumps’ true positive displacement pumping action and minimal internal losses achieve high efficiencies, as measured from pump shaft to hydraulic output power - lowering energy usage.

Let us help keep your process producing for a more sustainable future - safely, reliably and efficently.

Why Hydra-Cell®?

|

|