Accurately and Reliably Handling Your Process Liquids - Economy through Technology

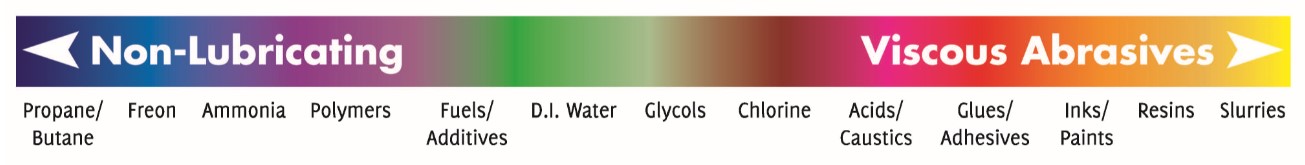

With the seal-less, packing-less design, Hydra-Cell® pumps safely, accurately and reliably handle many liquids. Dynamic seals and packing account for approximately 80% of pump servicing and unplanned maintenance, especially when handling non-lubricating, abrasive, corrosive liquids and liquids with micron-sized particles. Eliminating dynamic seals and packing significantly reduces the cost of ownership.

Protect Your Operators, the Environment and Save on Process Liquid Costs

No leakage – 100% containment.

No Unplanned Downtime and Reduce Maintenance Costs

Reliably handles non-lubricating liquids and liquids containing abrasive solids with no dynamic seals or packing to wear and replace.

Save on Your Energy Costs

True positive displacement pumping action gives efficiency of up to 90%.

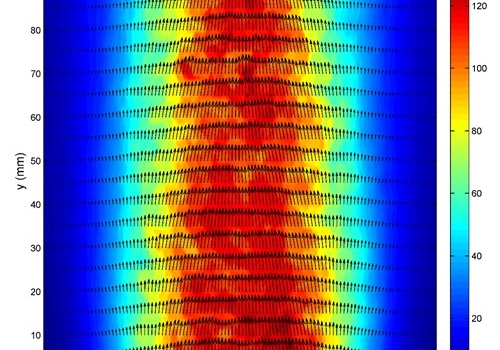

Consistent Process

Constant flow rate, independent of pressure.

Protecting Your Process

Low shear pumping action, even at high pressure of up to 200 bar.

Careers

Request a technical support meeting online

CALL +44 (0) 1252 816847