Reduce Costs and Improve Productivity with Hydra-Cell

Hydra-Cell seal-less pump technology

- Handles fines that can destroy pumps with dynamic seals

- Requires no fine filtration

- Minimal maintenance

- Can run dry indefinitely

- Outstanding energy efficiency

- True peace of mind with over 40 years partnering with world-class HPC manufacturers and the largest CNC machine tool manufacturers

Reliably handling coolant with suspended metal particles

Typically coolant filtration systems will filter down to 10 microns, however damage to coolant pumps with dynamic seals is often caused by having higher ppm of sub-10 micron particles. Hydra-Cell seal-less design eliminates this issue reducing operating and lifetime costs and increasing productivity.

Hydra-Cell seal-less design allows the pump to handle liquids with suspended solids from 0.1 microns up to 500 microns, reliably and consistently over many years. The wide choice of valve materials, such as ceramic and tungsten carbide, enables processing of materials ranked 10 on the Mohs’ hardness scale, such as diamond.

Energy efficient and reduced energy costs

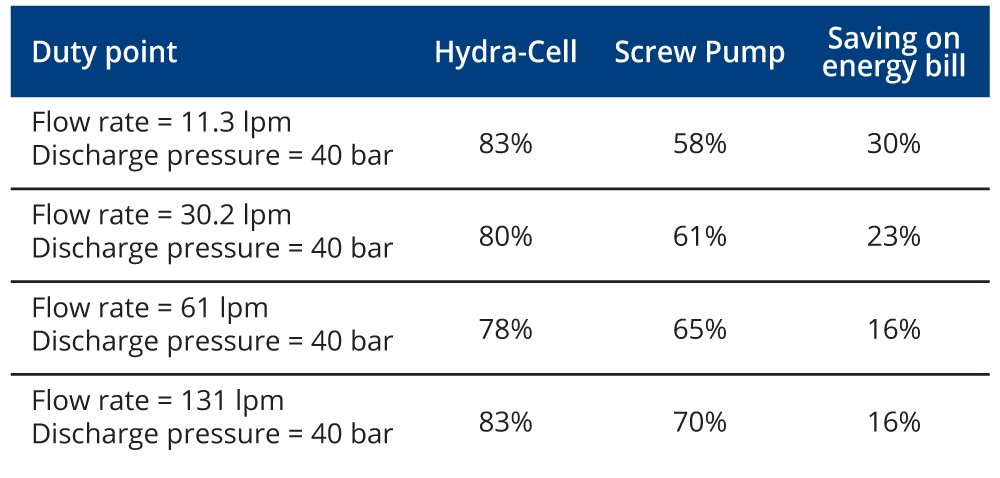

Being a true positive displacement pump, the seal-less design of the Hydra-Cell pump eliminates internal flow losses giving overall efficiencies of 78% - 90% (pump-shaft to hydraulic power) resulting in significant energy savings; with no dynamic seals, this is consistent year after year.

Long life and minimal maintenance costs

Any servicing is simple. With no dynamic seals wearing or tight internal tolerances to set, servicing can be carried out in any basic workshop. Depending on the duty, an annual oil change, and typically once every 2-3 years to replace a liquid end kit (€300 to €700 depending on specification) is all that is required. A true “fit and forget” solution.

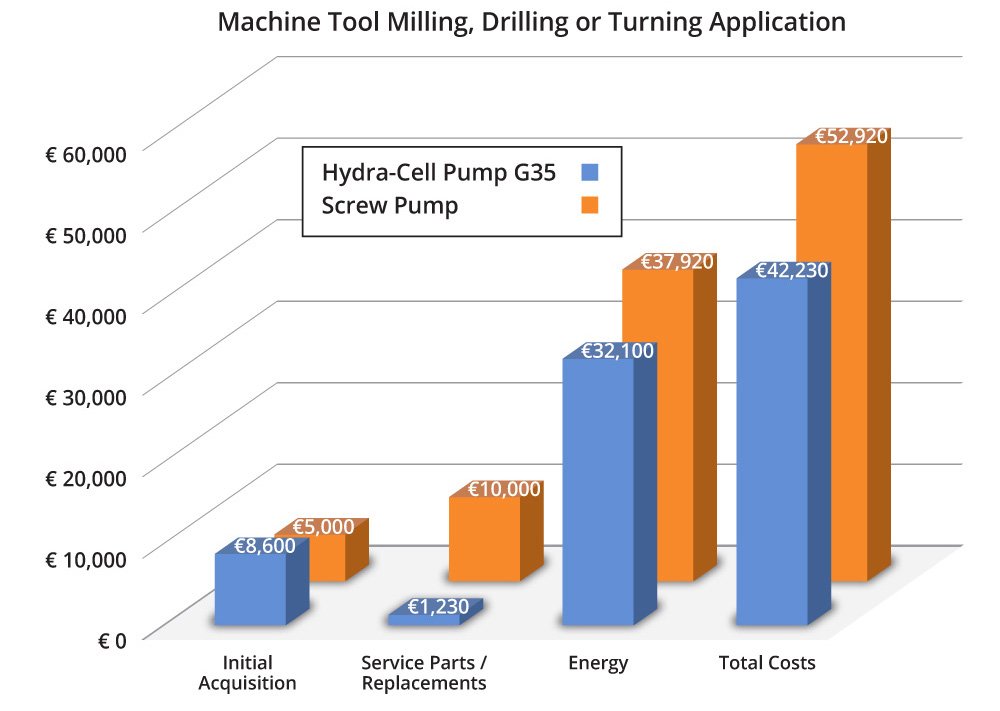

Lifetime Costs Comparison (5 years)*

Pump-Shaft to Hydraulic Power Efficiency Comparison**

Hydra-Cell seal-less pump technology

Reliably handling different cutting coolant technologies

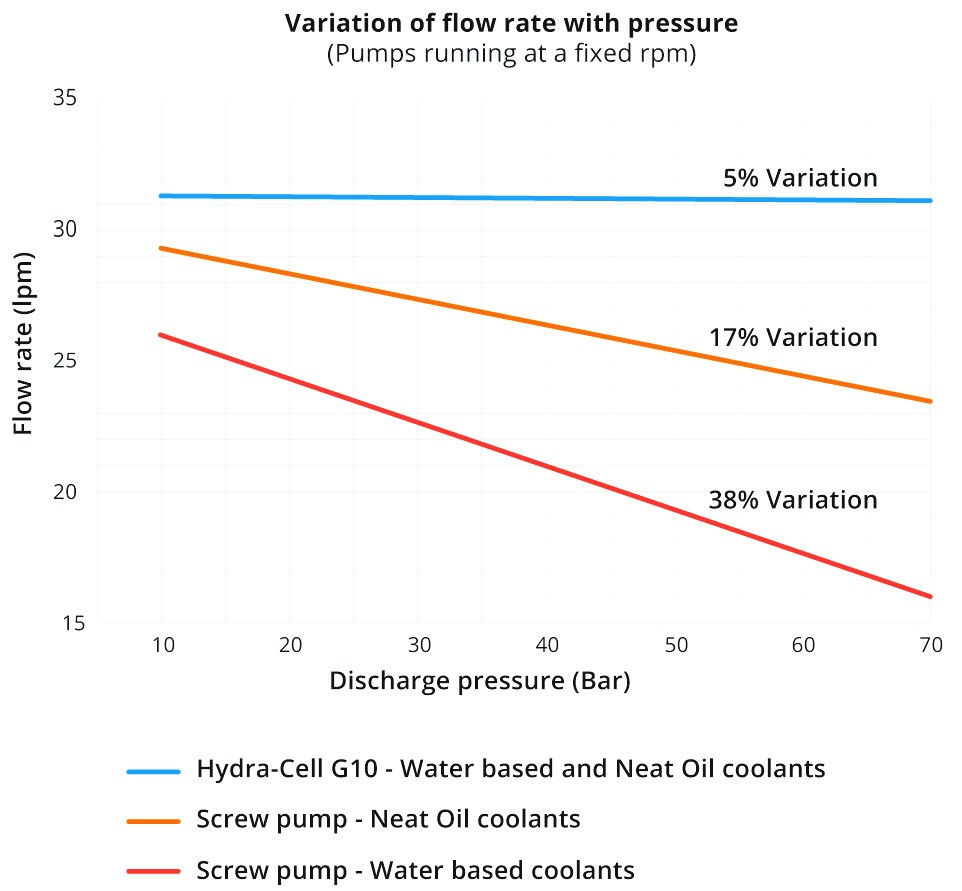

Different cutting tool liquids can vary in viscosity from thick oils at 20 mm 2/s to emulsions and synthetic water-based coolants a 1 mm 2/s. Hydra-Cell’s seal-less design ensures there is no reduction in flow rate with increasing pressure especially with low viscosity coolants.

Flow Rate Comparison