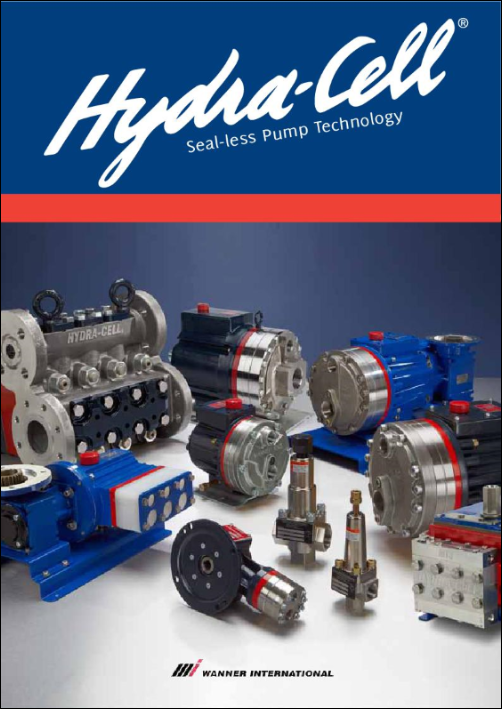

Hydra-Cell High Advantages for Machine Tool Applications

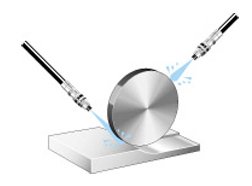

Electrical Discharge Machining (EDM)

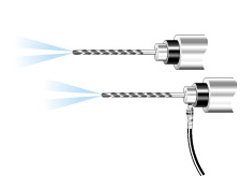

The injection of deionised (DI) water requires precise, consistent control down to very low flow rates at high pressures. DI water is corrosive, non-lubricating and can cause excessive maintenance with pumps with dynamic seals and packing.

Hydra-Cell’s seal-free, packing-free design, coupled with a constant accurate flow rate independent of discharge pressure, ensures a controllable dependable process.